Rotational Molding

Thin-walled, hollow parts that require tight tolerances can be manufactured using a rotational molding (rotomolding) process. Our consistent manufacturing process gives us the ability to create complex geometries in a single seamless part. We use proprietary resins and cost-effective, affordable tooling.

What Is Rotational Molding?

Rotational molding is a manufacturing method that produces parts fabricated from polymer resins, which can offer excellent chemical and environmental resistance. The resistant properties of selected polymer resins are aided by the seamless interior that results from the rotational molding process.

This seamless interior minimizes weak points where chemicals could potentially penetrate or react with the material. The homogeneous nature of the plastic structure enhances its resistance to various chemicals and corrosive substances.

A seamless interior also eliminates cracks or crevices where bacteria or contaminants could accumulate, enabling rotationally molded containers and vessels to serve in high-purity manufacturing operations.

Overall, rotomolded containers and vessels are valued for their ability to maintain their structural integrity and the durability and impact resistance they can offer, alongside their chemical and environmental resistance. Rotomolding also presents cost advantages compared to other manufacturing methods for an impressive return on investment.

The properties of rotationally molded containers or vessels benefit numerous applications within multiple industries, including aerospace, agriculture, automotive, mining, metallurgy, pharmaceuticals, and semiconductor fabrication.

We use the rotational molding process to create aerospace parts and high-purity containers. We also have the capability to manufacture a wide range of molded pieces in our ISO Class 7 Clean Room for high-purity applications.

Advantages and Disadvantages of Rotational Molding

| Advantages of Rotational Molding | Disadvantages of Rotational Molding |

|---|---|

| The ROI on parts over time can be higher than other manufacturing processes | Rotational molding may have a higher production cost than some alternative processes |

| This process supports complex geometries, which reduces part count and installation labor time | There are temperature constraints of the part, due to the process being limited to plastics |

| Seamless parts reduce potential failure modes | Mold modifications are required if the design is changed |

| Materials used are dimensionally stable, have a low crack propensity, and can service a wide range of process temperatures | |

| Durable parts that withstand impact during installation, operation, and maintenance | |

| There is a potential for weight reduction of the part |

Rotational Molding Process

Rotational molding offers manufacturers a cost-effective method to produce hollow, seamless parts using thermoplastic polymers. Polymer resin is placed in a mold, which is then heated and rotated on two axes to evenly distribute the melted plastic resin through the interior of the mold. As it cools, the plastic solidifies into the desired shape, vessel, or container. The rotational molding process yields components with a high strength-to-weight ratio, which also provides chemical resistance and corrosion protection.

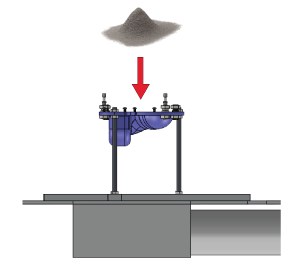

Step 1

A mold is mounted to a multi-axis rotational molding machine. Thermoplastic resin is placed inside the mold, and in some circumstances, components such as mounting nuts or brackets are inserted at this time as well.

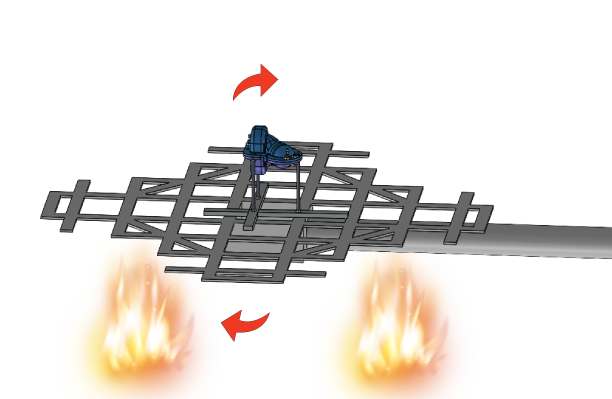

Step 2

The mold is rotated inside of an oven. As the mold rotates, the polymer becomes molten and forms an even layer across all internal surfaces.

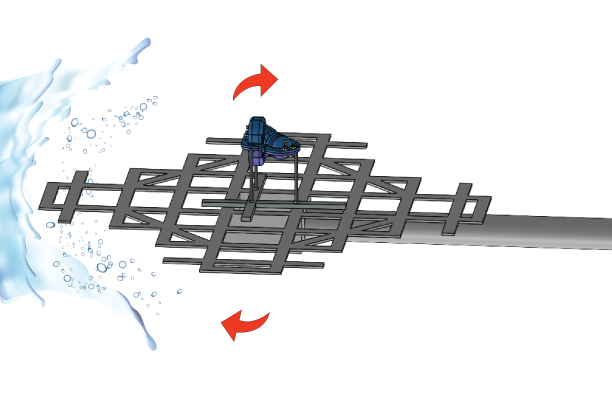

Step 3

The mold goes through a cooling process to set the newly molded plastic part in place.

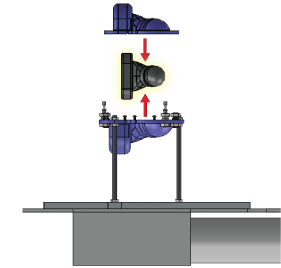

Step 4

The mold is removed from the machine and the plastic part is carefully taken out of the mold. The resulting seamless thermoplastic piece can be machined to tight tolerances, painted, or otherwise finished and assembled with other parts.

What Are the Best Materials for Rotational Molding?

We use a variety of thermoplastic polymers in our rotational molding process, including polyethylene, polypropylene, and PVC. We also offer proprietary resins. Resin selection depends on the specific requirements of each individual project. Factors such as durability, chemical resistance, availability, and cost optimization play important roles to help determine the ideal material.

Explore our materials listed below. Contact us to discuss the best material solution for your project.

| wdt_ID | Material | Application | Maximum Service Temperature | |

|---|---|---|---|---|

| 1 | PFA | Lining top coat, high purity vessels and fittings, high temperature applications, and chemical resistance. | 500°F /260°C | PFA |

| 2 | ECTFE | Chemical resistance for molded tanks, vessels and bottles. | 302°F/150°C | ECTFE |

| 3 | PVDF RMB 283 | Aerospace and semiconductor fluid tanks, ducts and fittings. Excellent physical properties, low moisture absorption and excellent chemical resistance, flame retardant. conforms to FDA No. 21 CFR 177.2510. | 260°F /127°C | RMB 283 |

| 4 | PVDF RMB 11008-3001 | Fluid tanks and molded ducts and fittings, excellent physical properties, low moisture absorption and excellent chemical resistance,flame retardant. Conforms to FDA No. 21 CFR 177.2510. | 260°F /127°C | RMB 11008-3001 |

| 5 | HDPE | Chemical resistance, long term UV stabilized high density co-polymer offering outstanding stiffness and processing. | 180° F / 82° C | HDPE |

| 6 | HDPE Health | High density co-polymer suitable for medical devices with USP class VI and Drug Master File Listings. | 180° F / 82° C | HDPE Health |

| 7 | Polypropylene | Impact propylene copolymer. Good chemical resistance. | 230° F / 110°C | Polypropylene |

| 8 | RMB437 Nylon 12 (Replaced RMB435 in 2013) | RMB 437 is a high impact non-halogenated flame retardant polyamide based resin. It is specifically formulated for aerospace ECS ducting providing excellent physical properties, low moisture absorption, good chemical resistance and ease of processing. | 220° F / 104° C | RMB 437 |

| 9 | RMB 421C Nylon 12 | RMB 421C is a polyamide based resin (ASTM D4066 – PA0422) specifically formulated for aerospace ECS ducting. Excellent physical properties, low moisture absorption and good chemical resistance combined with ease of processing. | 220° F / 104° C | RMB 421C |

| 10 | RMB 9103 Nylon 12 | RMB 9103 is an impact modified non-halogenated, non-phosphorus flame retardant polyamide based resin. It has been specifically formulated for aerospace ECS ducting with good physical properties, low moisture absorption, good chemical resistance. | 220° F / 104° C | RMB 9103 |

| Material | Application | Maximum Service Temperature |

What Products Are Made with Rotational Molding?

Here are some examples of the types of products manufactured using rotational molding:

- Storage tanks

- Containers

- Ducting

- Sprayers and tanks

- Cylinders

- Squared-off containers

- Bottles (can be threaded to accommodate caps)