Offshore oil platforms rely on caissons, or columns of steel, to serve as a critical part of their operation. Caissons house and protect equipment, such as seawater pumps and piping. These vital components are highly susceptible to corrosion and degradation as they extend into the splash zone and may be submerged in the ocean.1 A major oil company operating on the Gulf Coast needed to find proper treatment that could extend the lifespan of this critical equipment and avoid excessive downtime.

Challenge: Wind, sea, and waves create harsh environment for critical equipment

The harsh environmental conditions common to offshore oil drilling present numerous challenges to the integrity of critical infrastructure. The seawater discharge caissons in this offshore installation were previously constructed with fiberglass-reinforced plastic (FRP), which failed due to deterioration at the flange connections. Because of this failure, the caissons were approaching their end of life, a critical juncture that could potentially impact the platform’s operational capacity and safety.

Recognizing the urgency of the situation, the oil company engaged an engineering firm to manage the repair project. The engineering firm, in turn, contracted an established fabricator with experience serving the offshore customer base. This complex project required specialized expertise, leading the fabricator to subcontract with RMB Products for the critical lining and exterior coating of the repair.

Specifications: Short turnaround time and large components

- Repair time: To minimize operational disruptions, the time window for repair turnaround was restricted to four to five weeks.

- Structural integrity: The solution needed to preserve the caissons’ strength without adding excessive weight or altering their dimensions.

- Balanced expenditure: The chosen solution also needed to strike a balance between immediate repair costs and long-term maintenance savings.

- Material compatibility: Material compatibility presented another hurdle. The repair needed to address potential issues with dissimilar metals and ensure full corrosion protection.

- Size constraints: The repaired caissons had to fit within the fabrication and lining equipment capabilities of the chosen suppliers, adding another layer of complexity to the project.

The size and weight of the caisson components presented additional challenges. Some pieces, particularly those higher up in the structure, required very thick-walled steel due to the weight they needed to support. These components were so large and heavy that they nearly exceeded the capacity of RMB’s equipment. This necessitated a careful analysis of each piece, not just from a dimensional standpoint but also in terms of weight, to ensure they could be accommodated by the rotational lining machinery.

Solution: Aerospace application adaptation ensures project success

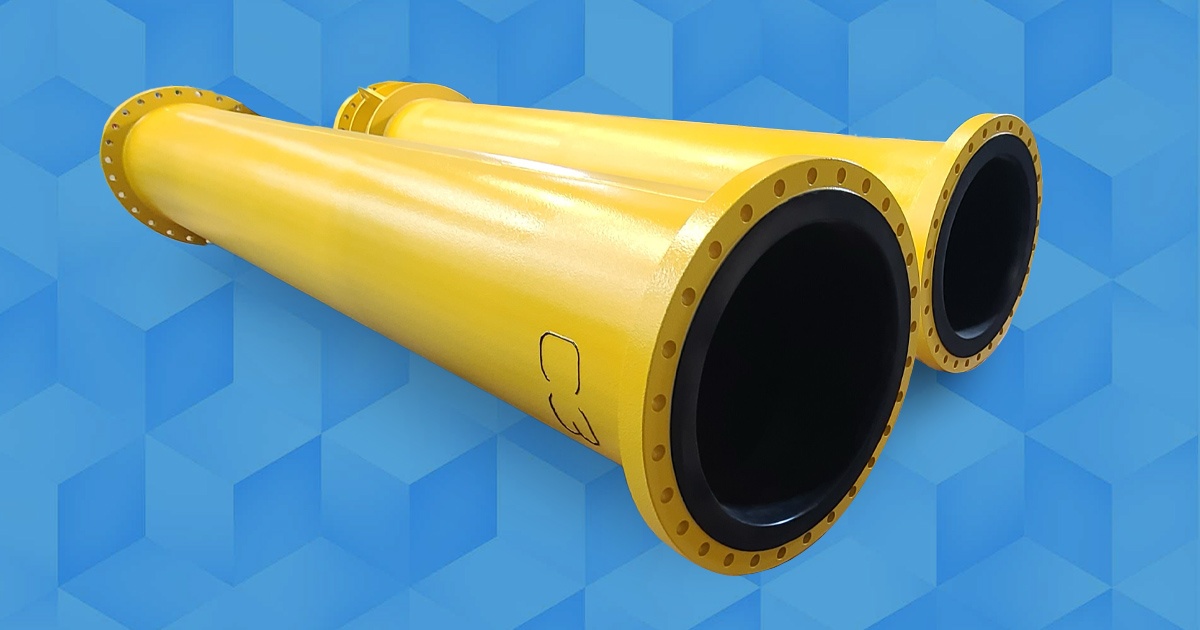

After considering the project requirements, RMB proposed and implemented an innovative solution utilizing their proprietary RMB BIO-ARMOR™ lining system. This proprietary blend of high-density polyethylene (HDPE) and antimicrobial additive is applied to the pipe and vessel by a rotational lining process. BIO-ARMOR protects against corrosion as well as 99% of the microbes that induce microbiologically influenced corrosion (MIC) and biofouling. This approach addressed all the challenges presented and offered several additional advantages.

The BIO-ARMOR lining system was selected for its superior corrosion resistance and durability in marine environments. The rotational molding process creates a seamless, impermeable barrier that protects the carbon steel caisson structure from degradation. Compared to FRP composite construction, the steel structure of the caisson provides superior strength. RMB expedited the application process and allowed for completion within the tight timeframe, minimizing downtime for the oil company’s operations.

RMB designed and installed specialized compression rings between the flanges, allowing for a precise amount of compression of the liner and ensuring optimal sealing and longevity of the repair. RMB used galvanized steel for the compression rings instead of stainless steel, ensuring the long-term integrity of the repair to avoid issues with dissimilar metals.

As another critical step, RMB staff worked closely with the engineering firm to modify the design of some components to address the size and weight challenges. They shortened certain pieces to ensure they could be properly handled and processed within RMB’s facilities.

This collaboration was crucial in finalizing a design where every piece was suitable for rotational lining without compromising the structural integrity of the caissons. The largest components were so massive that RMB rented special equipment to handle the material, as the parts exceeded the capacity of their standard material handling equipment and cranes.

The implementation of this solution involved close collaboration between the engineering firm, the fabricator, and RMB. The project execution included the following key phases:

- Early design collaboration: RMB worked with the engineering firm to ensure all components were compatible with their lining capabilities.

- Surface preparation and BIO-ARMOR application: RMB completed a thorough cleaning and preparation of the caisson surfaces, followed by skilled technicians applying the lining system according to RMB’s precise specifications.

- Comprehensive protection: RMB installed custom-designed galvanized steel compression rings, applied a specialized polysulfide sealant at material interfaces, and added a protective exterior topcoat.

The successful completion of this project within the specified period demonstrated the efficiency and effectiveness of the BIO-ARMOR lining system. It highlighted RMB’s expertise in providing tailored solutions for complex offshore infrastructure challenges.

Rotational lining supplies robust protective layer to reset caisson lifespan

The BIO-ARMOR system provided a robust protective layer without significantly increasing the weight of the caissons, maintaining their structural integrity and performance. This application effectively resets the clock on the caissons’ lifespan, pushing back the perceived “end of life” and providing a long-term solution.

RMB provided a 100% corrosion protection system, including an HDPE liner, exterior topcoat, and polysulfide sealant to address vulnerabilities at material interfaces. The polysulfide sealant, a technology transfer from RMB’s aerospace division, was particularly crucial in sealing the small gap between the liner and the exterior coating, preventing corrosion in this vulnerable area that will be exposed to the corrosive seawater.

The project also highlighted the importance of early engagement and precise planning. The custom compression rings had a projected lead time of 3.5 to 4 weeks. RMB reserved shop space in advance once the compression ring delivery date was confirmed to expedite the project once the parts arrived. This proactive approach, combined with thorough preparation of inspection and test plans, allowed for a compressed timeline without compromising quality or safety standards.

Biofouling and its impact on the oil industry

While biofouling wasn’t the main concern in this case, the BIO-ARMOR system’s anti-fouling properties provide additional protection against the potential build-up of marine organisms. Biofouling and MIC buildup are pervasive issues in offshore environments.2 The accumulation of marine organisms on submerged structures can lead to accelerated corrosion, reduced flow rates in pipelines and caissons, and increased maintenance costs.

Oil and gas platform with the wave of sea or gulf in the oil and gas industry. Construction for wellhead platform in the world of fuel energy.

The success of this project not only solved the immediate problem for the oil company but also opened new possibilities for addressing similar challenges across the industry. As offshore platforms worldwide grapple with aging infrastructure, particularly with caissons nearing their perceived end of life, this case study demonstrates a viable, efficient, and long-lasting solution.

Key takeaways: Early collaboration, innovative application techniques

The success of this project offers valuable insights for the offshore oil industry. Early collaboration with specialized suppliers like RMB proved crucial for ensuring project success and avoiding delays. The comprehensive solution provided by the BIO-ARMOR system, combined with carefully selected materials and application techniques, delivered a complete corrosion protection system for the caissons.

RMB demonstrated the ability to draw from and adapt the knowledge and expertise gained from another industry to solve unique challenges in offshore oil and gas applications. Advanced lining solutions can provide substantial long-term cost savings by extending equipment lifespan and reducing maintenance requirements.

By leveraging advanced materials, innovative application techniques, and early collaboration, this project demonstrates how a perceived end-of-life infrastructure can be given new life. It ensures continued safe and efficient operations in the challenging offshore environment. Plus, it offers a potential solution for other offshore operators facing similar challenges with aging caissons, addressing a widespread industry concern.

Request a quote for an advanced lining solution for your next project.